Pneu & Shell

Diploma Thesis 2016

University of the Arts Berlin

supervised by Prof. Dr. Norbert Palz, Prof. Dr.-ing Christoph Gengnagel

The project was supported by: Quantz, Solidian GmBH & DistTex

︎ concrete design competition prize

University of the Arts Berlin

supervised by Prof. Dr. Norbert Palz, Prof. Dr.-ing Christoph Gengnagel

The project was supported by: Quantz, Solidian GmBH & DistTex

︎ concrete design competition prize

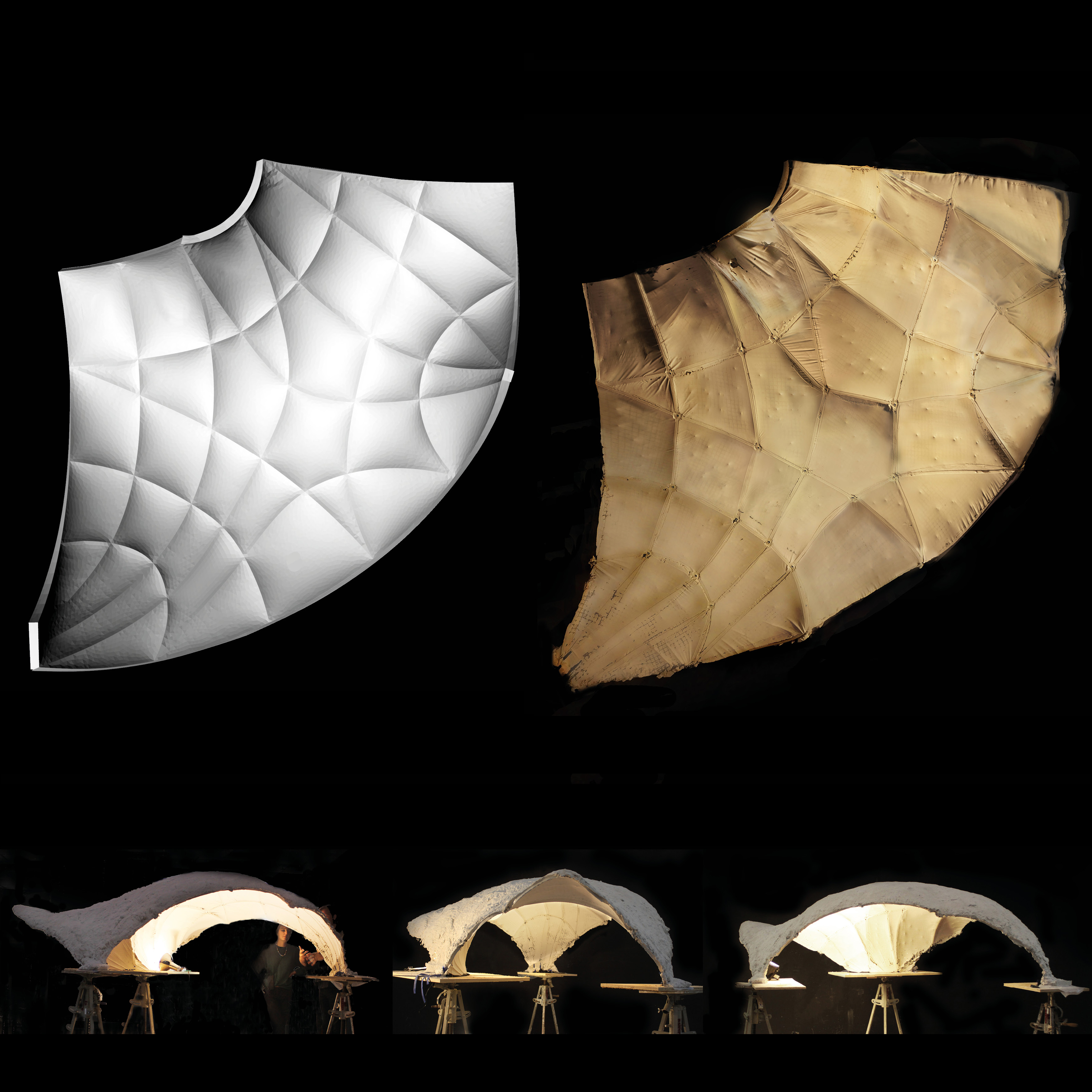

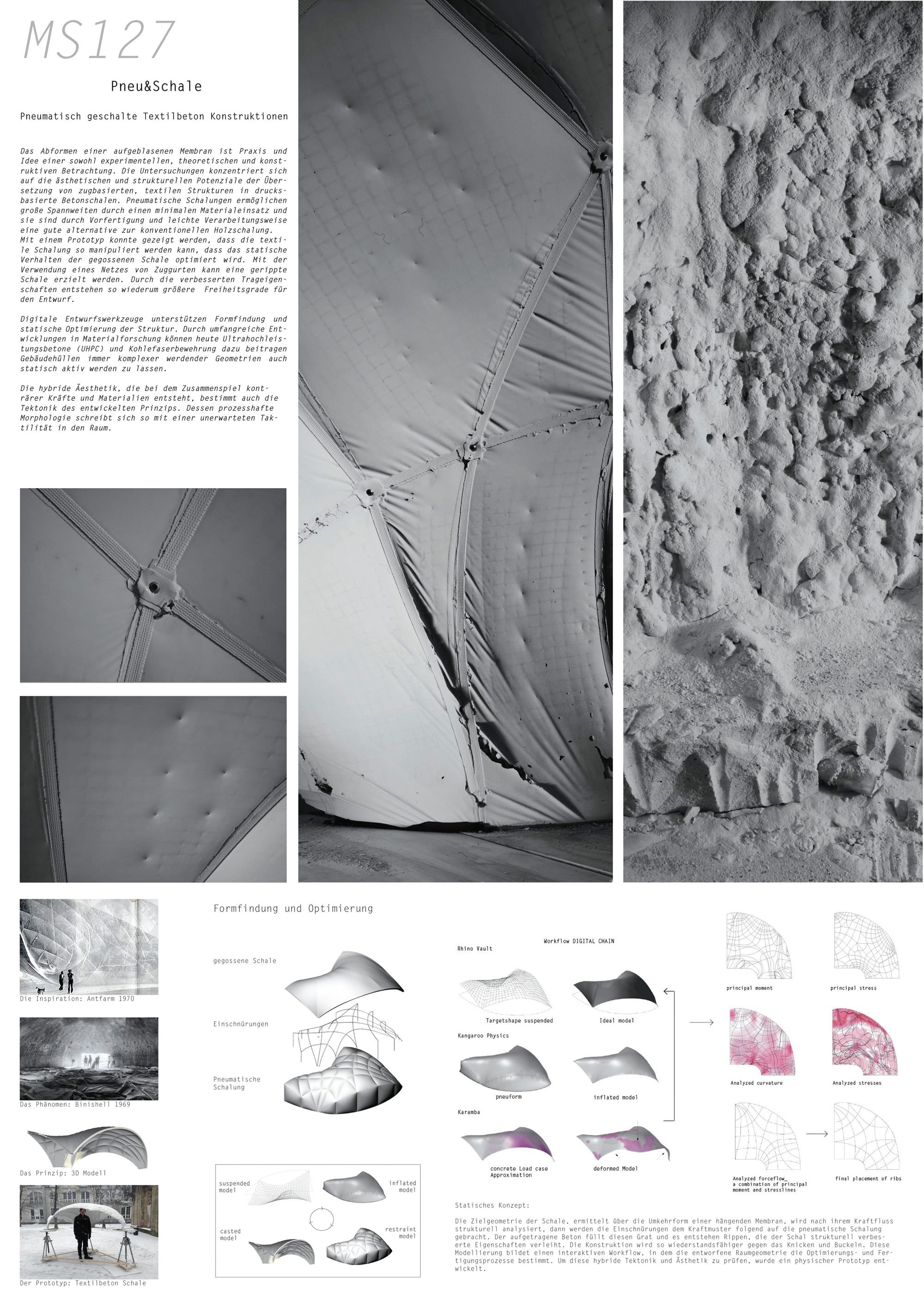

The experimental study delves into a novel construction approach employing pneumatic formwork and textile reinforcement, aiming to revolutionize the production of free-form concrete shells. Additionally, this project highlights an innovative computationally driven form-finding methodology, specifically tailored for crafting surface-active structural systems like shells, utilizing pneumatic textile formwork. Anticipated advancements in mineral and polymer materials, such as ultra-high performance concrete (UHPC) and carbon fiber reinforcement, hold the promise of enabling the construction of larger spans for composite shells in the future.

The research is centered on exploring both the aesthetic and structural potentials inherent in the transformation from tension-based inflatable structures to compression-based thin shells. Pneumatic formwork emerges as a game-changer, allowing the construction of expansive structures with minimal material usage. Its advantages include reduced labor intensity through prefabrication and on-site casting, presenting a significant departure from traditional casting methods.

The physical prototype showcased in this study serves as a tangible demonstration that the shape of an inflated formwork can be manipulated to enhance both the aesthetic appeal, accoustics and structural performance of the resulting casted shell. Employing a network of restraining ropes, a ribbed shell configuration can be achieved, facilitating the utilization of the shell for freeform geometry while averting the risk of buckling. This approach, referred to as Pneumatic Restraint Cast (PneuReCa), proves to be an effective method for fabricating complex geometries with reduced material consumption, leveraging a digitally-driven, topologically-optimized design process.

The research is centered on exploring both the aesthetic and structural potentials inherent in the transformation from tension-based inflatable structures to compression-based thin shells. Pneumatic formwork emerges as a game-changer, allowing the construction of expansive structures with minimal material usage. Its advantages include reduced labor intensity through prefabrication and on-site casting, presenting a significant departure from traditional casting methods.

The physical prototype showcased in this study serves as a tangible demonstration that the shape of an inflated formwork can be manipulated to enhance both the aesthetic appeal, accoustics and structural performance of the resulting casted shell. Employing a network of restraining ropes, a ribbed shell configuration can be achieved, facilitating the utilization of the shell for freeform geometry while averting the risk of buckling. This approach, referred to as Pneumatic Restraint Cast (PneuReCa), proves to be an effective method for fabricating complex geometries with reduced material consumption, leveraging a digitally-driven, topologically-optimized design process.